Welcome to our everything about Injection Mold China. We are a top plastic injection molding company that specializes in offering solutions for plastics manufacturing. Our experience and commitment to quality have made us the preferred partner of many businesses looking for reliable injection mold-making services.

Understanding Injection Molding

Injection molding is a flexible method of fabricating intricate or detailed parts with high precision. It works by injecting melt, typically plastic, into a mold cavity where it cools down and takes the shape required. The process is popular across industries because it is efficient, repeatable and cost-effective.

Advantages of Injection Molding in China

There are several reasons why you should choose to do injection moulding in china:

1. Affordable Production

China has lower costs for labor and infrastructure compared to other places which makes it possible for them to manufacture these parts at low prices.

2. Technology and Skill Level

Employment of skilled personnel alongside use state-of-the-art machinery guarantees high-quality outputs by Chinese manufacturers.

3. Faster Prototyping and Design Iteration

Fast turnaround times offered by china enable quick prototyping as well as design iteration leading to faster time-to-market for new products.

Our Injection Moulding Process

1. Design & Prototyping

We collaborate closely with clients on part designs optimized specifically for injection moulding. With advanced CAD software our team can create detailed prototypes ensuring manufacturability and performance requirements are met before production starts.

2. Material Selections

We provide thermoplastic materials such as ABS PC Nylon among others as well as thermosetting compounds tailored to suit different project needs during the manufacturing stage.

3. Tooling & Production

Having our own in-house tooling capability means we can produce precision molds at short notice using highest grade steels through advanced machining techniques which results into durable yet cost effective tools..

4.Quality Control (QC)

Throughout manufacturing strict QC processes including but not limited to inspection raw materials, in-process checks and final product validation are implemented.

Why Choose Us For Injection Molding?

1. Experience & Expertise

Having been in the industry for [X years], our vast experience enables us to deliver exceptional injection molded parts consistently.

2. Customization & Flexibility

We serve various sectors and allow project specific customization where necessary.

3.Global Coverage

Being based in China means we have access to wide supplier networks as well as other resources that can aid in seamless logistics management across different geographical regions.

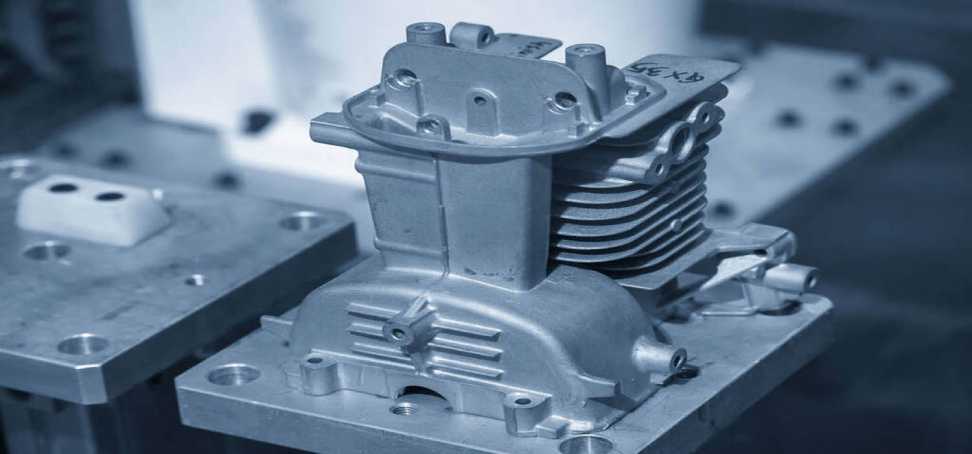

Leading producer Aluminum Die Casting Manufacturer

This is a comprehensive guide on aluminum die casting manufacturing. We are an industry-leading manufacturer dedicated towards producing quality aluminum die-cast components for diverse applications. Our facilities are equipped with advanced technology and staffed by skilled professionals who provide tailor-made solutions to meet your exact requirements when it comes to die casting.

What is Aluminum Die Casting?

Aluminum die casting refers to a highly versatile manufacturing process used for making intricate metal parts by injecting molten aluminum under high pressure into steel moulds or dies. The resulting products have good dimensional accuracy, surface finish, and strength properties which make them suitable for many different uses.

Advantages of Aluminium Die Casting

There are several benefits associated with choosing aluminum die casting:

1) Lightweight yet strong material

Aluminium alloys offer lightweight combined with high strength characteristics thereby enabling designers achieve weight saving objectives while maintaining required levels of structural integrity and performance in their designs without compromising safety margins where applicable.

2) Ability to produce complex shapes

1. Planning and tooling

We work with our customers closely to optimize part designs for die casting. Our engineers use advanced CAD software to create molds that enable accurate replication of complex shapes.

2. Selection of materials

To get the best mechanical properties and surface finish, we have tailor-made a range of aluminum alloys such as ADC12, A380 etcetera which were designed to fit different performance requirements.

3. Precision casting

Our high-tech die-casting machines together with skilled operators ensures consistent production quality for aluminium components.

4. Finishing and assembly

In order to achieve desired aesthetics and functionality of the final product, we offer various finishing options like shot blasting, powder coating or machining.Assembling services are also available where needed thus delivering complete finished assemblies.

Why Choose Us for Aluminium Die Casting?

1. Experience and expertise

Having worked on countless projects related to aluminium die casting over [X years] now; we know what works best in different situations thereby guaranteeing exceptional outcomes that surpass client expectations every time round.

2. Quality assurance

When it comes down to quality control; no one does it better than us! We follow strict quality control procedures throughout the entire manufacturing process so that all parts meet or even exceed industry standards set forth by regulatory bodies worldwide.

3. Client centeredness

We prioritize customer satisfaction and work collaboratively to understand and fulfill unique project requirements.

Summary

Throughout this complete guide, we’ve looked into injection molding as well as aluminum die casting in China. Injection molding is a cost-effective way of producing materials with cheap labor, advanced technology, and the ability to create prototypes quickly. We work closely with customers during the injection molding process, carefully choose materials, and enforce quality control with an iron fist.

On the flip side, aluminum die casting produces lightweight but strong components that are suitable for complicated designs or shapes. We design molds specifically for die casting while using various aluminum alloys to meet different performance needs. Precision is key when it comes to our finishing touches on castings which are then assembled into finished products according to specific requirements.

Frequently Asked Questions (FAQs)

Q: What is the lead time for injection molding projects?

A: Lead times can vary depending on how complex or large volume required by your project is – however fast prototyping/production achieved through our streamlined Chinese operations means shorter time-to-market new products.

Q: How does material choice affect quality of injected parts?

A: Material selection plays a crucial role in determining mechanical properties such as strength and stiffness; surface finish e.g smoothness or texture; durability – resistance against wear & tear etc.; thermal conductivity – ability to dissipate heat away from sensitive areas thus preventing overheating among others. This is why we provide thermoplastic & thermosetting materials based on each project’s unique specifications.

Q: What measures do you take towards quality assurance during manufacturing?A: We undertake thorough inspections at every stage beginning from raw material input up till final goods output so that no defective item passes through unnoticed within our system hence compromising customer satisfaction levels which remains at its peak throughout all engagements with us.

Have A Look :-